Chips production lines with packing

Production line and machines

Production line and machines

Still deciding? Get samples Still deciding? Get samples

Atlas International

Atlas International

Find Similar Products

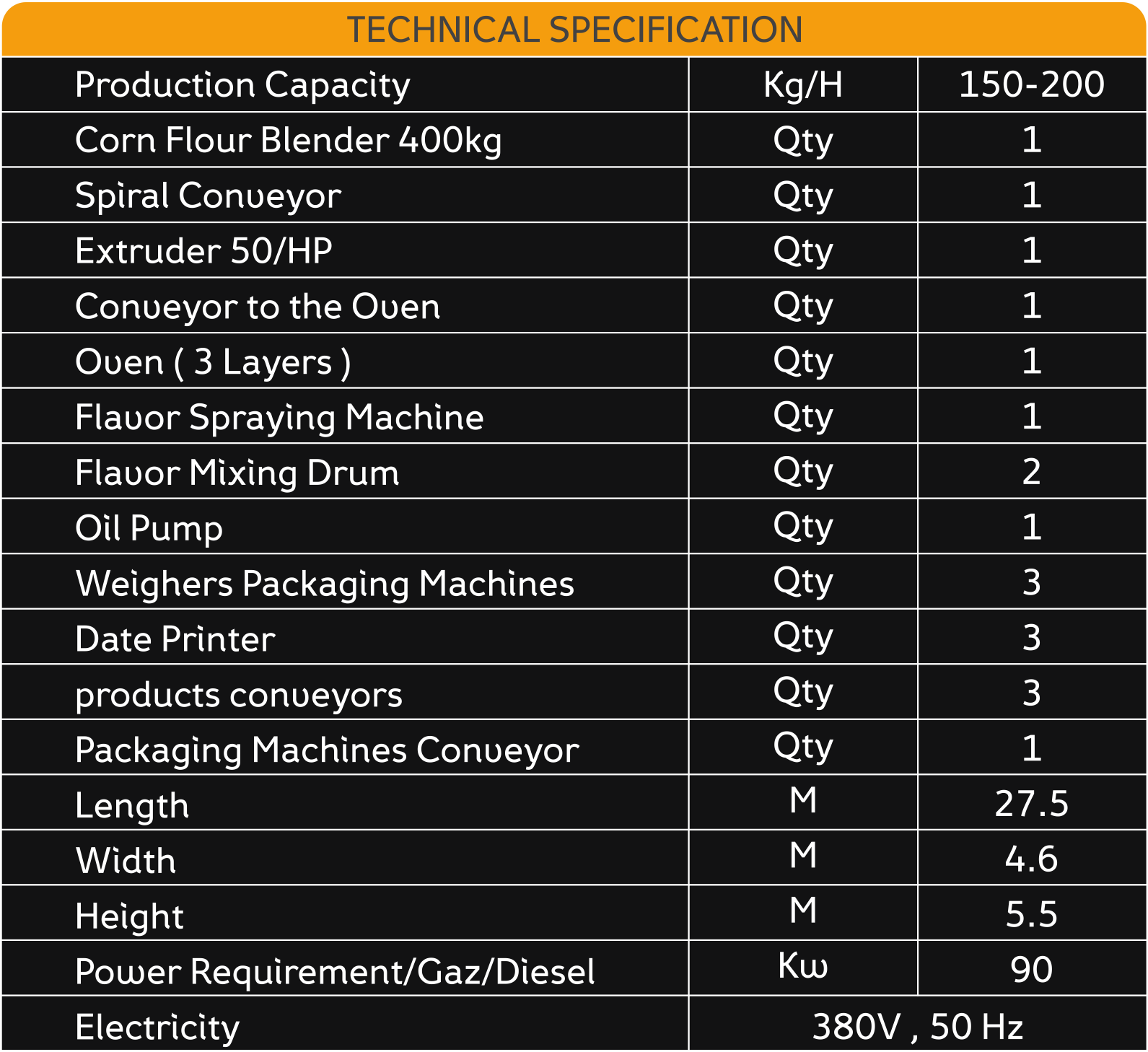

Production capacity : 150 - 200 kg per hour

Body material: made of stainless steel 304 (suitable for food products)

Number of required packaging machines: 3 machines

Line Sections

Corn Blender

Function: mixing and hydrating corn

Spiral Conveyor

Function: Transferring the Materials spirally from the corn blender to an extruder

Extruder

Model: ATLAS EXTRUSION 2020

Production Capacity: 150 - 200 Kg/h

Depending on the type of raw materials, the amount of flavor added and also the thickness of the grain

The extruder can produce up to 40 shapes of chips

Conveyor or Air blower :

Function: Transferring the Materials from the extruder to an oven

Drying Oven:

Equipped with 3 layers conveyor

Function: roasting and drying corn chips and fully extracting humidity

Working System : Customized

1- Diesel system (Riello Italy)

2- Gas system (Riello Italy)

Flavorer (Flavor mixing drum)

Function: spreading homogeneous mixture of oil and flavor on the outside of the chips.

Double oil & Flavor Blender

Function: Mixing oil with flavor and spraying it indsie flavor drum

Capacity: 400 Liters per tank

Oil pump

Function: Pumping the flavor with oil from blender to drum

Conveyor Line (Z-shape)

Function: feeding packaging machines

Working system: Fully Automatic

Filling and packaging weighing machine: (3 machines)

Filling system: Two towers of 14 weighing units from (High Dream) company with high specifications

Weighing system: It works from (10 - 1000) grams with high precision and conforms to European specifications

The machine is made of stainless steel 304 (suitable for food products)

It consists of: structure - filling device - internal system - external protection - feeding device

Work system: mechanical - air - servo

Holds quality certificates and

ISO 9001 - ISO 18001 - OHSAS 18001

And the European product quality certificate CE

For more details, please contact us for a quotation

About Us:

The company seeks to integrate with all its departments within its engineering and technical staff.

All of the company's products have been built on precise engineering standards, Starting with studying and engineering design by using modern scientific and technical methods, Passing through the implementation phase according to a strict standards and controls based on the latest technologies in industrial, electronic and pneumatic automatic systems.

The quality of the products that we offer is the core of our business, So we take great care in selecting the best types of pieces and metals within the international specifications which leads in maintaining the parts of the machine equipment’s that reduces the friction force and maintenance work, Which gives the machines the ability to work continuously up to 24 hours, Which reflects in the end on The actual life span of our products compared with other similar products and giving the company the ability to give its customers an open warranty for some countries and a mechanical guarantee for five years in others.